Lime Story

The Beginning and The End

CaCO3 = Lime Stone

Calcium Carbonate = Quarried Limestone and Pebbles

CaO

Fired Limestone = Calcium Oxide

CaO + H2O > Ca(OH)2

Fired Limestone + Water > Slaked Lime = Calcium Hydroxide

Carbonization Process

(On the wall, the lime comes in contact with air and releases oxygen)

Ca(OH)2 + CO2 > CaCO3

Slaked Lime + Carbon dioxide > Calcium Carbonate

Chemically identical to the original Limestone.

Started as limestone and ended as limestone

The Lime Source

A journey rooted in tradition begins as river pebbles and quarried lime, rich in calcium carbonate, are transformed into aged slaked lime putty. With origins dating from the ancient Greek and Phoenician civilizations, lime's durability and subtle beauty has carried it from the Old World into the New. This renewable, naturally occurring substance combined with modern technology has proven itself among the most resistant, aesthetic, and ecological building materials available on the market today.

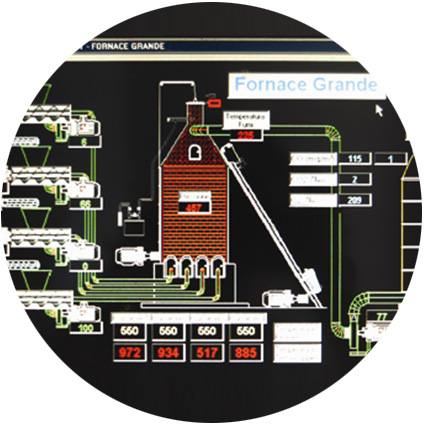

The Baking Process

During the baking process, ancient custom and innovation merge. Although the traditional brick barrel furnaces are still used, a computerized control system overseas each stage – from when the limestone first enters the furnaces until the process is complete a week later. The temperature is kept stable with the continuous addition of sawdust; highly sophisticated lasers purify the combustion fumes before they are released into the atmosphere.

The Slaking Process

The result of the baking process is quicklime. During the slaking stage, water is added to the material. This creates a dense liquid which is thoroughly filtered for any unbaked particles that could critically damage the quality of the final product. After the straining process is complete, the purified quicklime is sent to large tanks – the next stage in the slaked lime process.

The Aging Process

The aging process occurs in a large 500-ton-pit. To achieve the aged, authentic look of slaked lime it is imperative that the material set within the enclosure for at least six months. During this time, the product's chemical structure is altered to create the unique texture and appearance of aged slaked lime.

Before the final stage of the manufacturing process begins, the slaked lime is micro-filtered to ensure a creamy, smooth material free from impurities.

The Pigments

As carbonate crystals dry, they form a hard, invisible crust on the surface, which solidly binds to pigments. Thus, the color becomes an integral part of the plaster as is seen in Bueno frescoes done over wet lime putty. This chemical process is what makes lime plasters last and keeps the colors vibrant for decades, even centuries.

The Look

The look of lime is natural and soft. The light seems to go deeper into the plaster than Portland cement mixes and acrylic finishes. Whereas common modern building materials seem to have a flat, synthetic look to them, lime finishes have an iridescence that makes finishes look richer. There is a depth of color saturation and surface translucency.

Properties of Slaked Lime:

- Highly Breathable.

- Crack Resistant due to flexibility.

- Easy to Maintain.

- Naturally mold and mildew resistant. Due to its basic pH, lime acts as a natural biocide.

- Lime is produced without the use of plastics and harmful chemicals like most traditional plasters.

- Lime can sustain wet climates; it can stand up to rising damp and canal-side applications without delaminating.

- Self Healing: During construction, when buildings are under stress, lime is known to fill in the small cracks that can form.

- Environment: High Calcium lime is what farmers use in agriculture for enriching the soil. It is also used in heartburn medication and dietary supplements. In fact, it is the same material found in human bone.

- Easy to patch while fresh. The gradual setting process of lime plaster allows for easy repair when compared to many products.

- Historical Precedence: The ancient civilization of Egypt, Greece, and Rome used lime. Many of these creations have stood the test of time and remain beautiful, durable examples of fine architecture.

The slaked lime is now balanced, flexible, and ready to be produced into the finest plaster available on the market today. From authentic old world finishes to state-of-the-art contemporary, Italian Masters® has revolutionized the standard wall finish for the 21st century.